YWT provides a broad range of solutions for treating water and waste water. YWT’s main clients are industrial plants, particularly in the pharmaceutical sector, power, food, chemical and steel industries.

A key application of AAB includes the removal of free and emulsified hydrocarbons from petrochemical and similar wastewaters upstream of biological processes. This is been done in an effort to prevent toxic or inhibitory materials from hindering the biological processes downstream of the treatment unit.

Advantages linked with AAB systems include the fact that they are superior processes when compared with more traditional gravity-based settlement systems. This means that a reduction in space requirements can be achieved, and in terms of sludge thickening, a thicker sludge can be produced. Additionally, AAB systems offer the operator more degree of flexibility with regard to the system’s operating parameters.

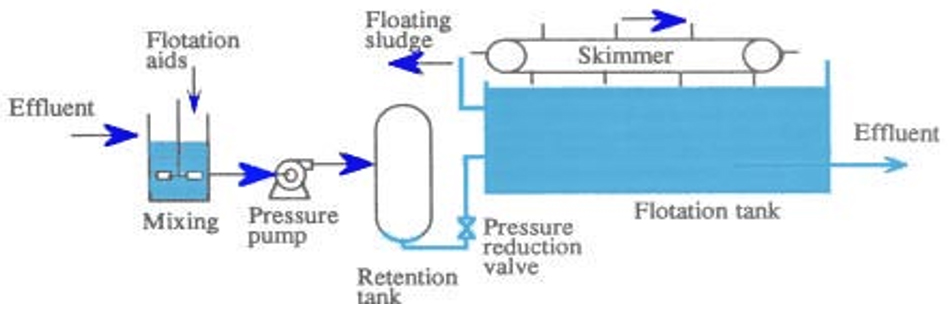

AAB is a purely physical process which operates based on a reasonably simple design philosophy. Incoming effluent may require pre-treatment as necessary, e.g. the addition of chemical coagulant(s) and/or flocculent(s) may be required with associated mixing and coagulation/flocculation stages. Adjustment of pH may also be a consideration to ensure optimum conditions for coagulation and flocculation.

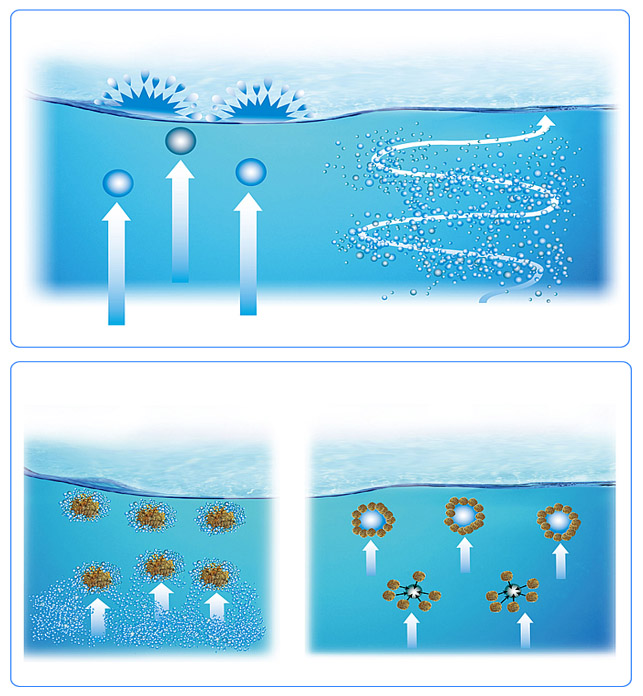

AAB systems are designed for pressurization and air emulsification of the total flow or, more commonly, the incoming effluent enters the AAB vessel where it comes into contact with a portion of recycled, treated effluent. The percentage of the total effluent flow into which air is emulsified under pressure and subsequently recycled will be determined by several factors. Increasing the pressure within the vessel where the air is being emulsified ensures that a higher concentration of air mixes into the liquid phase than is possible at atmospheric pressure. Once this portion of saturated effluent enters the flotation tank, the pressure is released back to atmospheric pressure. This immediately results in the recycled flow becoming supersaturated, resulting in the generation of micro-bubbles as the dissolved air comes back out of solution. As these bubbles rise due to Buoyancy they attach to, the solids or oil grease & chemical flocs in the vessel, causing them to float to the surface where they are retained, by buoyancy, and subsequently removed by a mechanical skimmer.

YWT provides a broad range of solutions for treating water and waste water. YWT’s main clients are industrial plants, particularly in the pharmaceutical sector, power, food, chemical and steel industries.