YWT provides a broad range of solutions for treating water and waste water. YWT’s main clients are industrial plants, particularly in the pharmaceutical sector, power, food, chemical and steel industries.

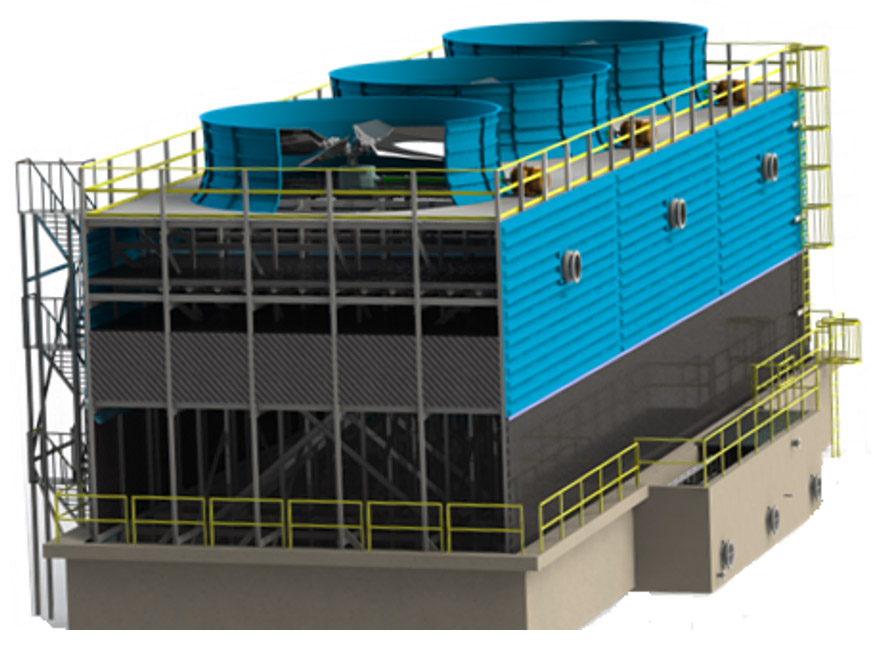

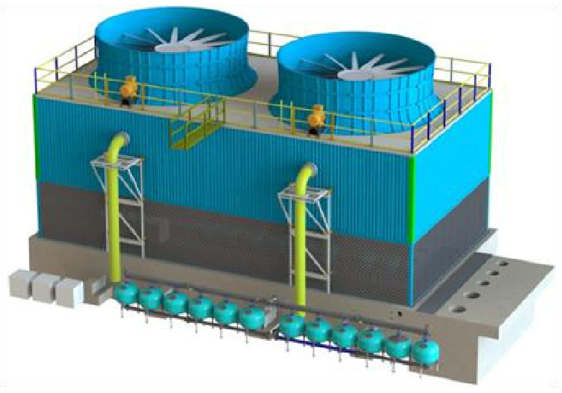

YWT India with YWCT, its Partner\Promoter from Israel is supplying FRP Counter Flow Cooling Tower having ‘100% plus capacity’ suitable for water flow, through the required design range and approach.

YWT India is focusing strongly, on pultruded FRP Field Erected Cooling Tower In Indian and around market

YWT India – YWCT Cooling Towers’ appealing, aesthetic looks, hygienic, anti-fouling and efficient fills, clear basin water owing to PVC Air Filters, shall be in sync with the rest of the structures of your state-of-art Plant.

· Thermal Design in MRL SOFTWARE

· Structural Design in 3D, With of Finite Element Analysis for Structural Stability, If required

· Compact and Strong Structure, Proven Assembly program, not prone to failure/ collapse.

· Lower Pump Head, and Lower Power Consumption on Fan.

· Custom Required foot-print / area.

· Our project delivery is the “FASTEST” in India.

· Closed Loop Hot Water Distribution And Air Inlet (FRP piping) System instead of Open Hot Water Basin which is prone to decay, water loss, bio growth and fouling.

· Durability, ease of inspection & maintenance, long life.

❖ 3-D SOLID WORKS VIRTUAL MODEL

❖ TABLE TOP PHYSICAL MODEL

❖ REMOTE PROJECT MONITORING (IP)

YWT India – YWCT focusses in medium size Pultruded FRP Industrial Cooling Towers from 1000-18000 m3/ hr capacity for PRECISION PROCESS APPLICATIONS. YWT India – YWCT incorporates world’s latest structural design features prevalent in Europe, Israel, Russian region. YWT India – YWCT has excellent precision design capabilities on 3-D Solid Works. Many local suppliers, despite having age-old experience in cooling tower industry, have ACTUALLY lesser design experience and lesser merits in Pultruded FRP structural design in 3-D

YWT India – YWCT has introduced Specialized PVC Air-Filters/ Louvers to screen off all open Air-Inlet sides of the cooling tower from outside debris, birds, worms, leaves, bagasse fibres, etc. entering into basin and mixing in circulating water system. It also reduces exposure of basin, water, tower internals and structures to sunlight – thereby checking biological growth. Use of expensive biocide in water treatment regime can be contained reducing overall water treatment costs significantly. For Bagasse Fired Boilers used in Sugar Industries / slop fired boilers in Distilleries, this small device/ feature / innovation is especially useful.

USER FRIENDLY TOWER INSIDE DESIGN

YWT India – YWCT JV has further improved and upgraded its cooling tower construction features. We have incorporated more advanced structural design, aesthetic finish / very unique, aesthetically coloured, and user friendly maintenance stairways and walkways, inside and outside the cooling tower.

In simpler words, the cooling towers besides having EXCELLENT PERFORMANCE and extremely user friendly, will be easy to maintain.

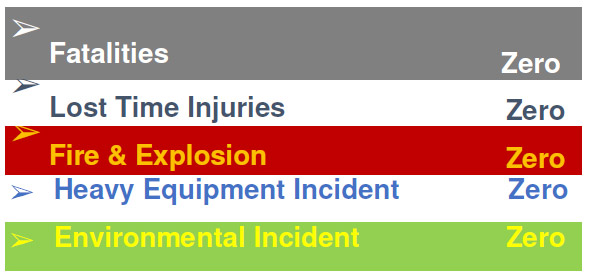

Fire accidents in power, distillery, refinery and process cooling towers are not uncommon. Source of fire may be hot works, welding, an explosion in motor or a short circuit or combustible gases making way into the water header etc. Fills and tower internals, PVC materials and low quality, non-FR Grade FRP are most vulnerable to fire. Good Fire Retardant grade fills and drift eliminators, PVC louvers should be used in cooling tower to prevent fire from spreading to fills and other parts of cooling tower.

YWT India only uses special FIRE RETARDANT FRP by using Aluminium Hydrates and other retardant compounds in the MOC for distillery and refinery application. Likewise, FR grade robust PP Fills made as per relevant CTI, ASTM, UL and FM standards are used for fire hazard processes. These materials are more expensive and safer than those used in power plant cooling towers.

It is IMPORATANT to perceive the potential fire hazards in distillery application cooling towers and use only FR Grade and good Quality FRP, Fills and internals.

YWT and YWCT jointly executed and commissioned several FRP cooling tower projects in India and abroad during the past 4 years.

The projects involved approximately 50,000 man-hours with ZERO incidents & ZERO accidents, ZERO near-misses and ZERO recordable incident.

❖ All Cooling towers were erected in record time. The cooling tower performance is excellent. Workmanship, quality and safety are satisfactory as per client.

❖ YWT Project and Workers Team are well familiar with site safety rules and regulations, compliances, labour standards and both project/utility sides have easy access to each other and enjoy excellent working relationship and work as a team.

YWT India-YWCT JV business model is ideally suited for generating maximum attention on small and medium size cooling tower projects and clients, YWT India has a division which is dedicated to services around the cooling tower and other water treatment circuits. Hence, performance can be assured for longer period.

In such a scenario, bigger infra-cooling tower suppliers may tend to lose sustained focus and after sales service, over the years to small projects and clients.

YWT India-YWCT JV with its select focus, dedicated team, prompt and personalized services shall be an ideal vendor & partner for your project.

YWT provides a broad range of solutions for treating water and waste water. YWT’s main clients are industrial plants, particularly in the pharmaceutical sector, power, food, chemical and steel industries.